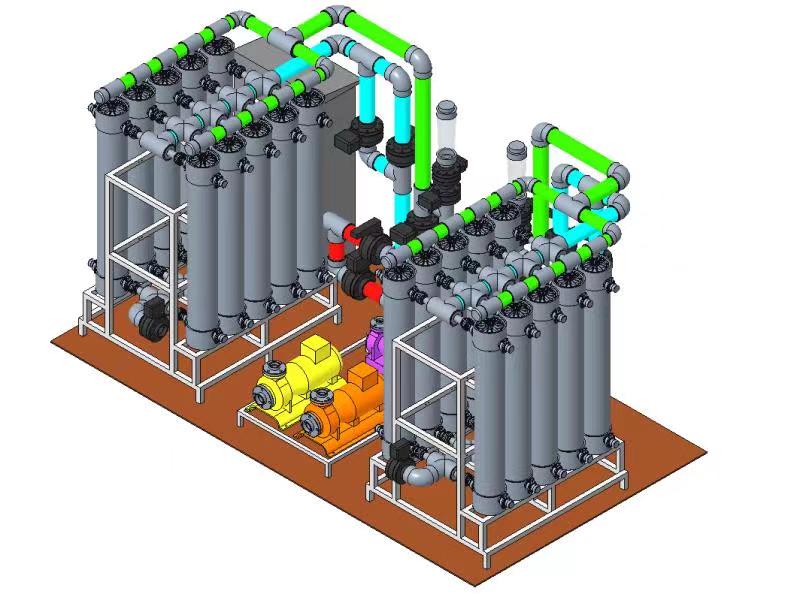

LINER CERAMIC MEMBRANE FILTER

Linear ceramic membrane integrated equipment is a wastewater treatment equipment specially designed for small factories. In line with the concept of "harmlessness, reduction, and resource utilization", no chemical reaction occurs in the wastewater treatment process, no chemicals are added, and the reuse of wastewater is truly realized.

Product advantages:

1、Scientific statistics

2、Anti-fouling

3、Adaptability and flexibility

4、Compact structure and small footprint

5、High level of automation

6、Wide range of utihity

7、Cloud/Remote control

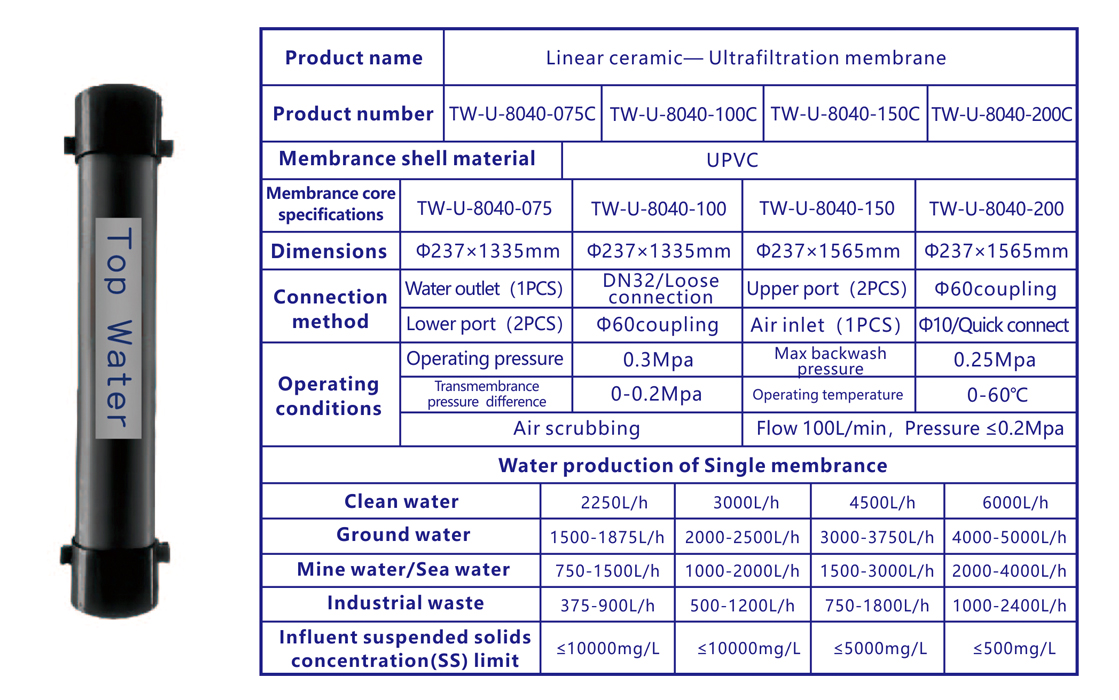

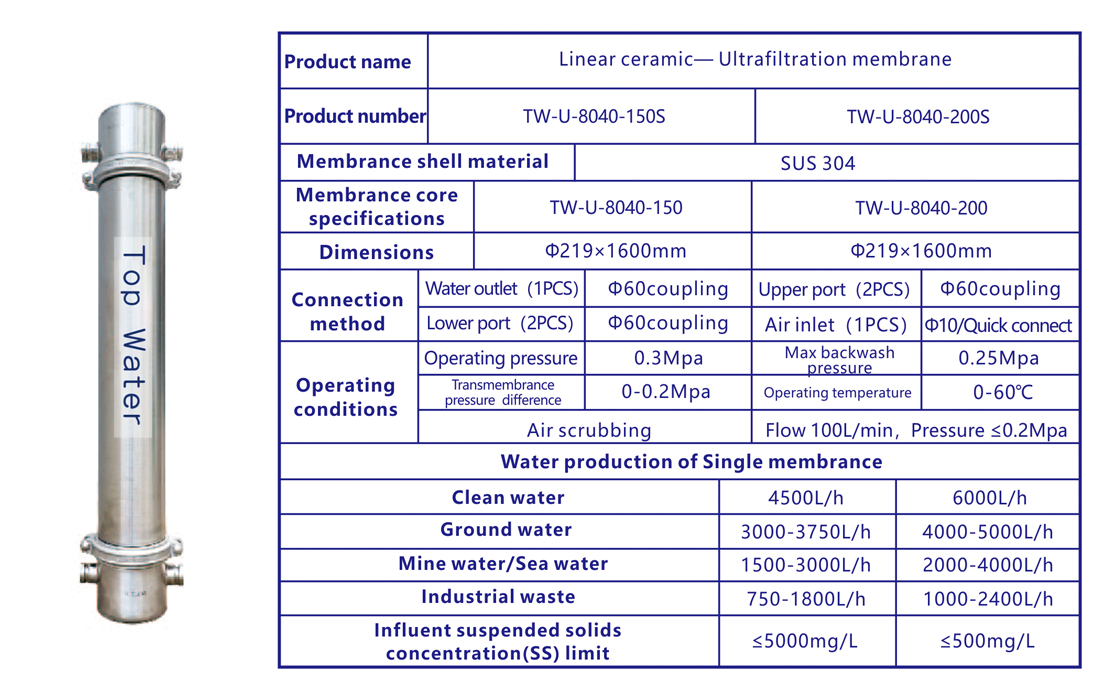

Linear ceramic membrane filters are: TW-MU-8050-15, TW-U-8040-075C, TW-U-8040-150S and other models. The detailed parameters are shown in the figure below.

Our technical capabilities cover areas:

Textile industry:High-concentration printing and dyeing wastewater, washing wastewater treatment and reuse.

Chemical industry:Material preparation wastewater, process water and other water.Treated to discharge under the standards.

Machinery manufacturing:Washing wastewater, cooling water, process water, etc. Treated, reused, and discharged in compliance with standards.

Metal casting industry:Cooling water, waste pickling acid liquid, etc. Treated and reused.

Daily chemical industry:Production waste water, synthetic washing waste water, surfactant waste water, saponification waste water, etc. are treated and reused, and discharged in compliance with standards.

Petrochemical industry:Treatment and discharge of oily wastewater, oilfield reinjection water, cooling water, and equipment cleaning water.

Food industry:Treatment and discharge of oily wastewater, oilfield reinjection water, cooling water, and equipment cleaning water.

Rubber industry:Cooling water, cleaning wastewater, sulfide wastewater, etc., wastewater treatment and discharge up to standards.

Pharmaceutical industry:Treatment and discharge of wastewater such as equipment flushing water, raw material treatment water, and equipment cooling water.

System solution:

1.Consulting planning 2.Site investigation 3.Projecting/Design 4.Technology comunication 5.Visit/reserch 6.Law/standard

7.Experiment report 8.Project implementation 9.Joint commissioning inspection 10.Operation and maintenance service

Application of integrated equipment in wastewater from ten major industries:

Solar wafer industry Electrophoresis industry Stone processing industry Ceramic production and processing industry Metal parts cleaning industry Alloy casting processing industry Glass fiber production industry Plastic processing industry

Optical grinding processing industry

- 2019-10-11 Removal effect and cause analysis of micro-polluted… >

- 2019-09-30 Sewage treatment equipment maintenance and precauti… >

- 2019-08-21 Conditions that must be known about the choice of s… >

- 2019-08-14 Chinese medicine extraction wastewater treatment - … >