Top Cooling Recycle System

Principal Description of Our Top Cooling Recycle System.

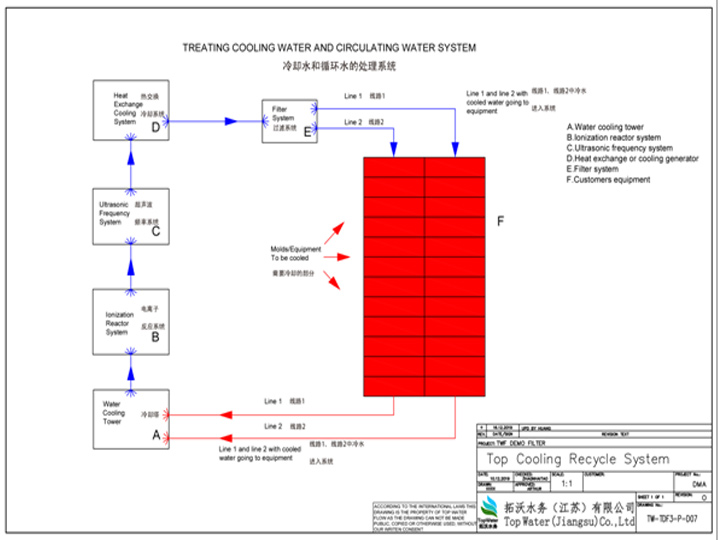

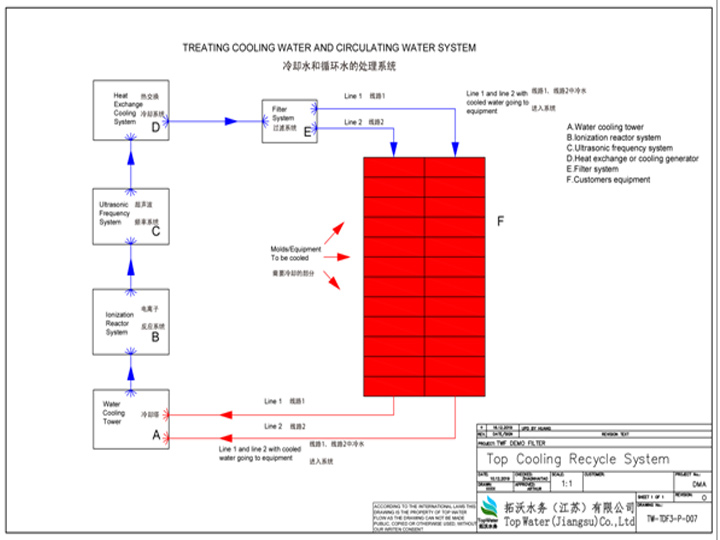

The complete system consists of six main parts. However, each project will be evaluated individually with specific needs.

See attached principle treatment schema with a basic guideline of installing the various equipment including customer’s equipment position.

Biofilm is a Trojan horse for pathogenic bacteria in all water systems.

Why treat cooling and drinking water systems.

1. Cooling system is mainly installed to cool down various hot industrial machines or other uses as industrial size air condition systems and drinking water system as well.

When cold water meets hot/warm areas, it

is common to get biologically growth also named biofilm.

Cooling tower is also open water source that easily collect dead insects and

bird manure and other organic wastes in the water.

2.Biofilm growth inside pipelines and production equipment will reduce the effect of pumping the cooled water through any systems.

3. Biofilm grows quickly, and therefore it needs to be constantly treated.

The

development of biofilms

The

development of biofilms is an usual way in which bacteria grows in nature. It

is deemed that under appropriate environmental condition, most of the

microorganism is able to form biofilm.

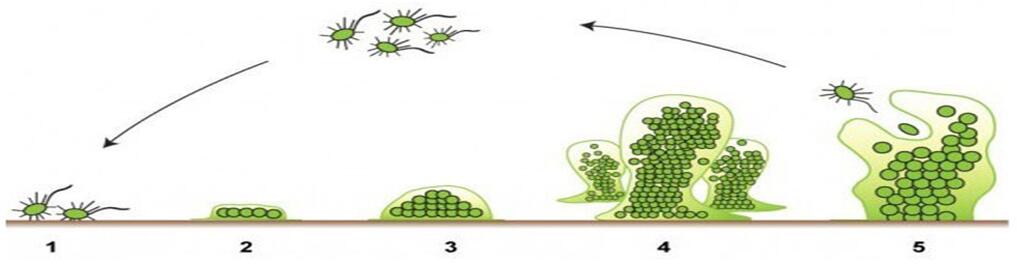

The formation of biofilms is a dynamic and complex process that we can divide it into five stages:

- Stage 1. Reversible attachment of the bacterium to the surface. Weak bond between the bacterium and the substrate that happens in barely 1 minute.

- Stages 2 y 3. Irreversible attachment to the surface with an initial growth and division phase with the production of a protective exopolymer and the final development of the colony with the dispersion of colonizing cells. The irreversible attachments are formed during a period of between 20 minutes and 4 hours.

- Stage 4. Growth and maturation. The resulting bacteria form a micro-colony around the attachment point. If the conditions are appropriate, an organized colony will develop. Along the maturation phase, the biofilm becomes adapted to the presence of nutrients, oxygen and the population changes. It's estimated that the development of this phase takes from 2 to 4 days.

-

Stage 5. Dissemination of colonizing cells. Finally,

some bacteria release themselves from the biofilm matrix so they're able

to colonize new surfaces, closing or starting the cycle.

The biofilm formation, attachment, maturation, dissemination and recovery process develops in barely 5 days.

Biofilms: a survival strategy of bacteria

The growth as a biofilm increases the possibility of survival of bacteria through mechanisms such as:

a) It acts as a “shield”, protecting the microorganisms against elements such as biocides or antibiotics, and it reduces the possibility of dehydration.

b) It increases nutrient availability for bacterial growth.

c) It makes the transference of genetic material (ADN) possible.

Control and removal of biofilms

The attached bacteria is much more resistant to biocides and to the conventional cleaning method than those that are free-swimming.

The control and removal of the biofilm must be a critical control point. It is essential to follow an appropriate protocol, both in the presence of animals as during a production break.

It has been seen that for removing the biofilm the cleaning with alkalis is more effective than cleaning with acids.

4. Each equipment has its importance in the treatment

process.

Each alphabetic letter is

marked on attached drawing.

a) Water cooling tower is the major source of biological growth because it is often an open system that easily collect organic matters.

b) Ionization systems will add chosen ionization to the water and ionization levels will be regulated by sensor to the local regulations of wastewater or drinking water if that should be the treatment case. Ionization will make an oxidation process, in which will kill all organic living in the water over time.

This ionization treatment will not add any chemical or color to the water, and it will not damage to the pipelines or equipment in the treated cycle.

c) Ultrasonic frequency system is usually installed in front of heat exchange or cooling generator, which will remove scaling in the cooling system and therefore serve a better functional effect on the equipment. Sometimes the ultrasonic frequency system is installed separately in front of molds and other extra protection of this equipment.

d) Heat exchange is mainly established to reuse the hot and cold energy. Cooling generator is adding cold energy to selected flow and this equipment needs clean surface to transport the energy into the liquid as much as possible.

e) Filter system is installed to collect dead bacteria and also other organic matters.

This is to maintain the quality of the liquid flow. These medias are most often in really small amounts, so it will be plenty with a type of small bag filter for handling these tasks.

When starting up a new ultrasonic frequency system, it will be more waste for one period, because scaling will start diluting and peal of the system.

f) Customer’s equipment is often installed in the end of the cooling treatment system, to get as cold water as possible. Our treatment system is also used in bigger water depot tank where we can install a small circulating system to maintain the water free of biological growth.

We can also see the maintenance cost is dropping parallelly with a longer lifetime and more functional operation on industrial equipment and we know it also makes healthier/more secure drinking water where this should be the treatment.

Top Water Jiangsu suggests that all industrial water related operating systems should be inspected and evaluated, in matter of which treatment is best for the industrial operations and public health. Top Water Jiangsu is willing to inspect the existed water system, make the right treatment plan with the cost of equipment/service and further investment return on our equipment.

Top Water Jiangsu have some recycling basics:

“Reduce,Reuse,Recycle, Return of Investments”.

- 2019-10-11 Removal effect and cause analysis of micro-polluted… >

- 2019-09-30 Sewage treatment equipment maintenance and precauti… >

- 2019-08-21 Conditions that must be known about the choice of s… >

- 2019-08-14 Chinese medicine extraction wastewater treatment - … >