Top Ceramic Recycle System

Description of Top Ceramic Recycle System.

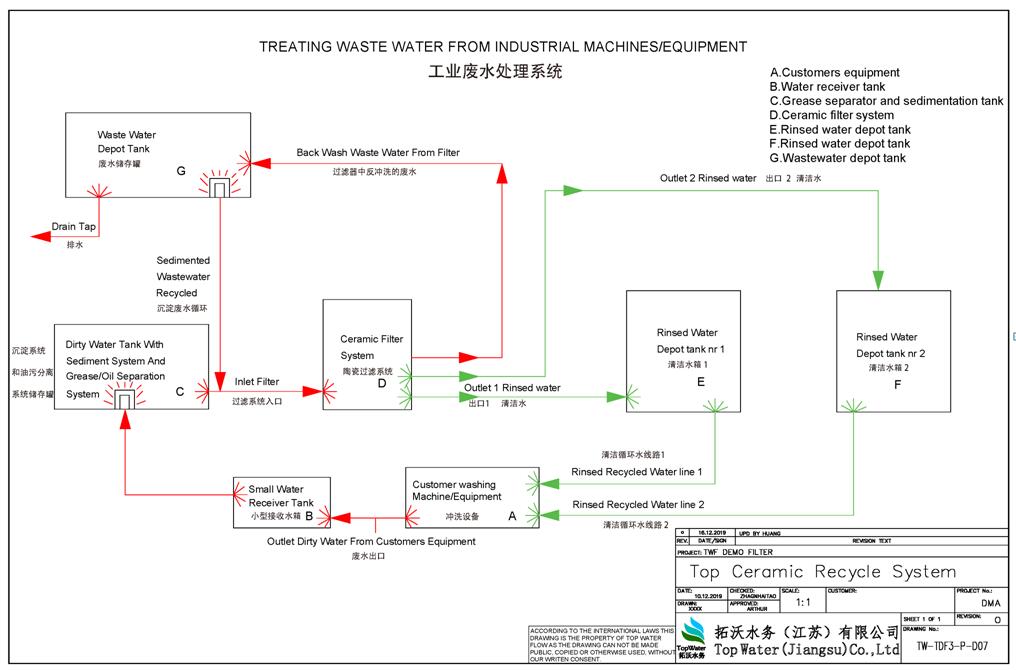

Top ceramic recycle system consists of six main parts: wastewater depot tank; water receiver tank; grease separator and sedimentation tank; ceramic filter system; rinsed water depot tank and the customer’s equipment as well. However, based on the guideline of the system, we will also evaluate each project and provide customized plan according to specific needs.

Please see the Top Ceramic Recycle System schema with a basic guideline of installation plan.

Reasons to recycle and reuse process water

· Process water in various industries is mainly installed to clean or mix various medias in various industries.

· It requires special storage for the wastewater and the delivery is often expensive.

· The local government has been more and more strict on wastewater treatment. The law requires the industries to find solutions to recycle the water in the best way.

· Some companies change the process water every 3 hours, and some reuse the water for 3-5 days before pumping into depot tanks for further treatment. The wastewater treatment plant will add a mix of chemical to process the treatment, which will charge both chemical and the delivery of wastewater.

Problems of reusing the process water without

treatment

· Take the process water of metal wash machine as an example. The waste water would accumulate many steel particles after resue for several times, which reduces the effect of cleaning work.

· Industry that reuse process water usually have high maintenance on the equipment because particles and waste in the water will plug and damage the equipment.

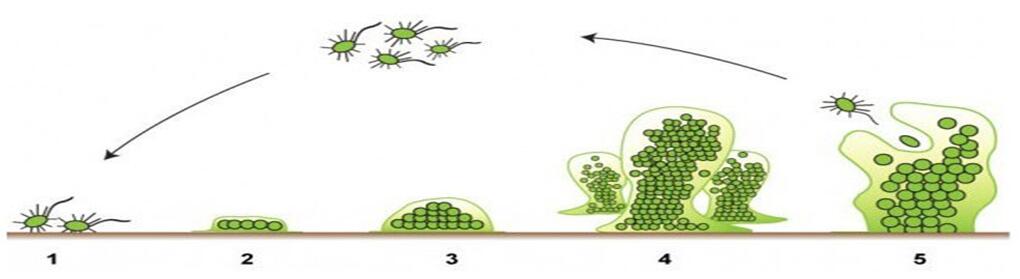

· Biofilm can cause problems in production line, which ceramic filter system will reduce bacterial and it can supply with some other technologies to fix the problem in total.

Ø Stage 1. Reversible attachment of the bacterium to the surface. Weak bond between the bacterium and the substrate that happens in barely 1 minute.

Ø Stages 2 y 3. Irreversible attachment to the surface with an initial growth and division phase with the production of a protective exopolymer and the final development of the colony with the dispersion of colonizing cells. The irreversible attachments are formed during a period of between 20 minutes and 4 hours.

Ø Stage 4. Growth and maturation. The resulting bacteria form a micro-colony around the attachment point. If the conditions are appropriate, an organized colony will develop. Along the maturation phase, the biofilm becomes adapted to the presence of nutrients, oxygen and the population changes. It's estimated that the development of this phase takes from 2 to 4 days.

Ø Stage 5. Dissemination of colonizing cells. Finally, some bacteria release themselves from the biofilm matrix so they're able to colonize new surfaces, closing or starting the cycle.

The biofilm formation, attachment, maturation, dissemination and recovery

process develops in barely 5 days.

8.Each part has its importance in the treatment process:

a) Take the metal wash machine/equipment as an example:

The process water for metal wash machine gets dirty and oily after reusing for several times. Detergent is used in the washing process to clean the parts properly. This is a typical way industry to be used as a guideline of recycling water.

b) Waste water

depot tank (Unit G) is used to collect the wastewater from various machines,

where the water will be pumped to the next phase for further treatment.

Some customers can pump the water directly to the Unit C.

c) Dirty water tank with sediment and oil/grease separation system (Unit G) will remove oil and sediments before the water goes into ceramic filter system (Unit D).

d) Ceramic filter system (Unit D) will filter down to 0.1 micron in particle size, which will remove the remaining particles and most bacteria in the water.

The ceramic filter system would not remove chemical in the process, which means

the users would save the amount of chemical/detergent in the recycling process

for cleaning parts.

Rinsed water goes into rinsed water depot tanks marked with Unit E and Unit F for further use. The reason of setting up two tanks is that one tank is used to rinse water at all times, so when dirty water goes into dirty water tank, then rinsed water is ready if needed to be reused in the system. When the system treats a small amount of wastewater, it is normally needed one rinsed water depot tank. The back wash waste from ceramic filter will be sent to wastewater depot tank (Unit G).

e) Rinsed water tanks (Unit E and Unit F) can be measured with needed amount of chemical for further reuse.

f) Wastewater depot tank will collect waste from the backwash of ceramic filter system. When the tank is filled up, the wastewater will rinse through the ceramic filter system again to reduce the water and get more concentrated waste before it is drained out.

Top Water Jiangsu suggests that all industrial water related operating systems should be inspected and evaluated, in matter of which treatment is best for the industrial operations and public health. Top Water Jiangsu is willing to inspect the existed water system, make the right treatment plan with the cost of equipment/service and further investment return on our equipment.

Top Water Jiangsu has some recycling basics:

“Reduce,Reuse,Recycle, Return on Investment”.

- 2019-10-11 Removal effect and cause analysis of micro-polluted… >

- 2019-09-30 Sewage treatment equipment maintenance and precauti… >

- 2019-08-21 Conditions that must be known about the choice of s… >

- 2019-08-14 Chinese medicine extraction wastewater treatment - … >